The implementation framework provides key steps to design and execute field trials for incorporating recycled materials in road construction.

The implementation framework outlined here is adopted from Ecologiq reference guide ‘Product and Material Trials for Recycled Material Use’. The framework follows a 7-step process:

- Assess your trial idea

- Plan your trial

- Site evaluation and selection

- Product design evaluation

- Construction

- Performance monitoring

- Reporting

1. Assess your trial idea

An initial assessment of the trial idea is important to validate and determine the scope of the trial. Some questions to help assess the idea include:

- Does the trial support priority materials?

- Will it contribute to a circular economy?

- What are the current standards and specifications available for this product/application?

- Are there any major OHS or environmental concerns?

2. Plan your trial

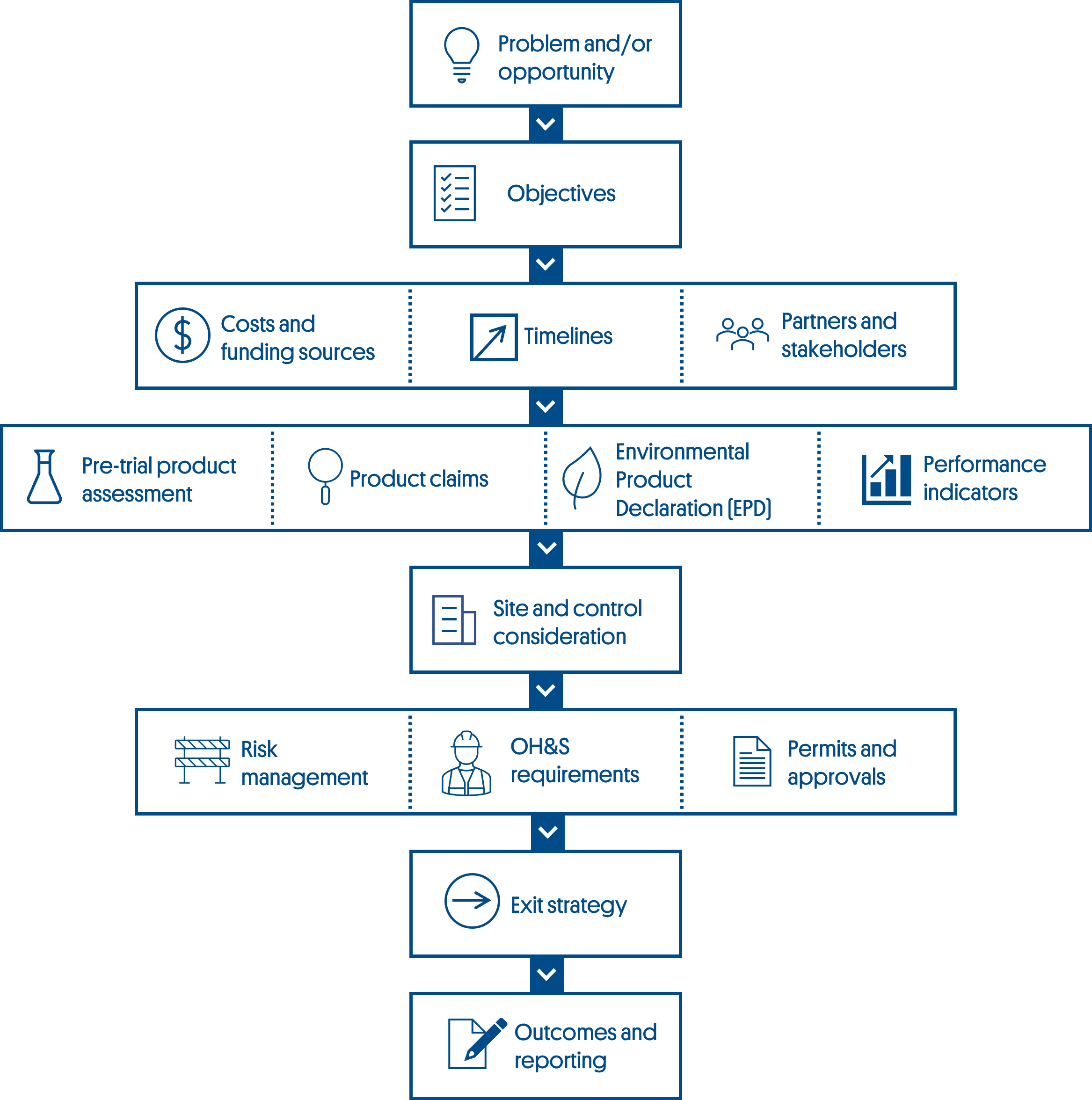

The below decision tree provides the considerations required to plan a successful trial from the idea conception all the way to the product's end of life.

3. Site evaluation and selection

The selection of a suitable site for a field trial will depend on factors including:

- funding and resource availability

- risk profile

- recommendations from suppliers

- size of the site required

- control sections

- composition of site, including traffic, road geometry, number of lanes, bike/parking lanes, speed bumps, kerbs, and so on

- climatic conditions

- existing surface condition and desired performance outcomes (that is, targeting a specific performance failure type)

- community impact.

4. Product design evaluation

This includes advice on required testing prior to construction and proof that the product or design meets an existing specification. Suppliers should provide National Association of Testing Authority accredited test results for all required properties.

For crumb rubber and recycled plastic asphalts, the product design evaluation includes:

- evaluation of the modified binder

- evaluation of the asphalt mix design.

Download sample evaluation templates

5. Construction

Key considerations during the construction process include preparing for construction, site planning, good communication between stakeholders, quality control and assurance, pavement design, and health, safety and environmental effects. Information that should be recorded includes:

- product manufacture details

- sampling regime of products (at time of production)

- laboratory testing results of the production mix

- placement and instalment procedures

- equipment details

- safety documentation

- OHS documentation and monitoring (for example, fuming)

- on-site pavement testing (paving temperatures, asphalt thickness, density)

- quality assurance documentation

- general trial observations

- communications.

6. Performance monitoring

Performance monitoring is an essential step in any trial. Quantitative measures of product performance should be sought and recorded where possible.

Performance monitoring of recycled materials containing pavements should include pre- and post-trial condition assessments. The extent of testing will depend on budget, application, and the aim of the trial. These provide useful information to road asset owners in making informed decisions when using alternative materials.

Pre-trial condition testing may include:

- pavement strength evaluation

- ground-penetrating radar testing to determine the structure of the existing pavement

- crack detection using a Network Survey Vehicle for the collection of roughness

- rutting and texture data and visual assessment of cracking and rutting to identify areas of patching.

Post-trial condition testing may include:

- visual assessments

- cracking

- rutting

- roughness

- surface texture

- skid resistance.

Monitoring regime and duration

The trial duration will influence monitoring frequency, however it is usually appropriate to monitor immediately after construction and then at specific intervals which should be collaboratively decided. It is recommended that a visual assessment be completed every 6 to 12 months.

Example monitoring regime

- Short-term performance monitoring (<2 years)

- Pre-trial-testing

- Post-trial testing at 0, 6, 12 and 24 months.

- Long-term monitoring (>2 years)

- Pre-trial-testing

- Post-trial testing at 0, 6, 12 and then every 12 or 24 months

Councils usually conduct digital condition surveys every 4 years to assess the condition of the road network to help prioritise capital investment programs. The data collection may consist of crack detection mapping and measurement, ravelling, potholes, roughness, rutting, surface texture, and stripping. This data is uploaded into a pavement management system for analysis and prioritisation of works and can be used as part of the trial monitoring process.

7. Reporting

Reporting and documentation of the trial process should be completed at every stage of the trial process and may include:

- concept proposal (for initial assessment)

- trial plan and proposal

- project execution plan

- project/trial update reports

- final report and summary report

- lessons learnt report.